3 Point Pivot Frame

Our Expedition Vehicle utilizes a 3 point pivot frame to support and isolate the camper and the storage boxes from the twisting of the Fuso FG truck frame.

The Mitsubishi Fuso FG 140 4x4 chassis is designed to allow the frame to twist along the longitudinal axis. This enables the axles to stay parallel to, and as a result, the tires to stay in contact with, the ground to the greatest extent possible. The downside to this design is that it produces extraordinary twisting forces on anything bolted directly to the frame rails.

I did not believe that any North American production camper could survive these twisting forces, so we elected to adopt the same 3 point pivot frame used on other vehicles, such as Unimogs, and on previous FG projects such as Darrin Fink's RUF AATREK and Carl & Mary Hunter's FG/Bigfoot.

Here are some examples of the twisting forces generated by the FG frame:

Darrin Fink's RUF-AATREK Torque Free Subframe test:

Darrin's company, RUF, designs and manufactures highly engineered Expedition Vehicles based on Mitsubishi Fuso products. He works closely with Mitsubishi Fuso North America and delivers only vehicles meeting their engineering, safety and regulatory standards. RUF is North America's only known source for factory approved Fuso based Expedition Vehicles. Highly recommended for well engineered vehicles.

Hackney FG Expedition Vehicle full articulation tests:

|

|

|

This is the wrinkling in the forward wall of the garage during the full articulation test. This amount of twist is introduced in only four feet / 1.22 meters of longitudinal FG frame length.

A 3 point pivot frame consists of a rectangular frame that is solidly attached to the truck frame at one end and pivots on a center mounted point on the other end. The pivot point can be located forward or aft, with corresponding advantages and challenges for each location. We chose a rear pivot point due to the garage construction and the desire to keep the storage boxes on as consistent an axis as possible.

In our design, the pivot frame is rigidly attached to the truck frame at the forward end of the base of the camper, which is the aft or rear wall of the garage.

The garage, genset mount, EZ-Up storage box and the shop storage box are un-pivoted and rigidly attached to the frame.

All storage boxes aft or rear of the rear garage wall are attached to the pivot frame.

The rear bumper is part of the pivot frame.

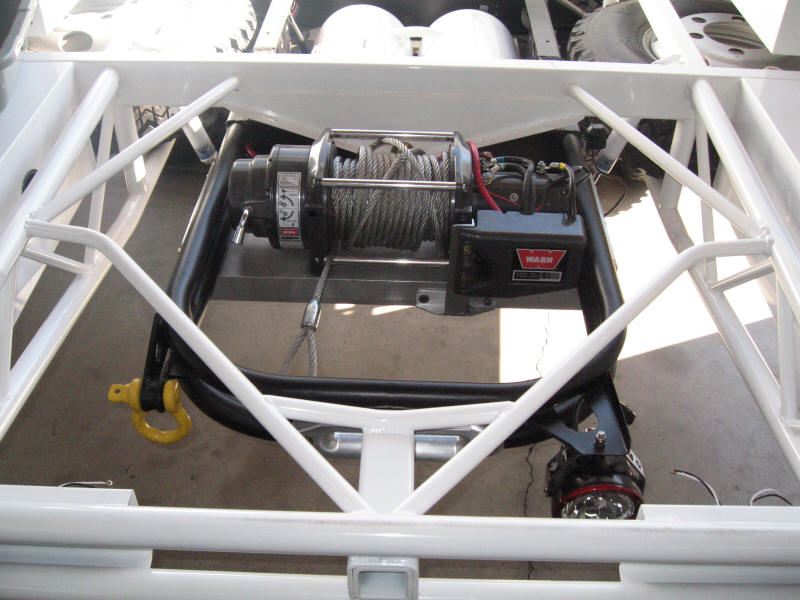

The rear winch is rigidly attached to the FG truck frame.

3 Point pivot frame photos follow.

Raw pivot frame photos

Raw rear pivot point

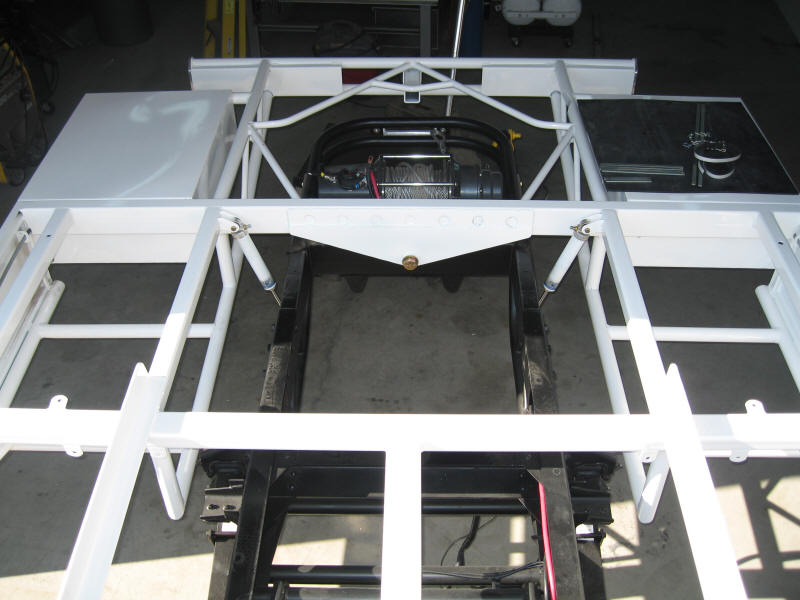

Finished 3 point pivot frame. In these photos, the white portions pivot and the black portions are rigidly attached to the FG truck frame.

Fox 50/50 shock used to dampen the lateral motion of the pivot frame.

Rear pivot point and Fox 50/50 shocks used to dampen the lateral motion of the pivot frame.

Rear pivot point and Fox 50/50 shocks used to dampen the lateral motion of the pivot frame.

Fox shock mounts. Apologies for the poor quality of this photo.

Version one rear winch mount. Black portions are rigidly attached to the FG truck frame, white portions pivot on the pivot point partially hidden by the winch drum & cable.

Pivot bolt drilled with safety wired J Clip

Version two rear winch mount & pivot bolt. Black portions are rigidly attached to the FG frame, white portions pivot.

Finished chassis ready for camper install.

Finished chassis ready for camper install.